US12480735 - Cocking system for a crossbow

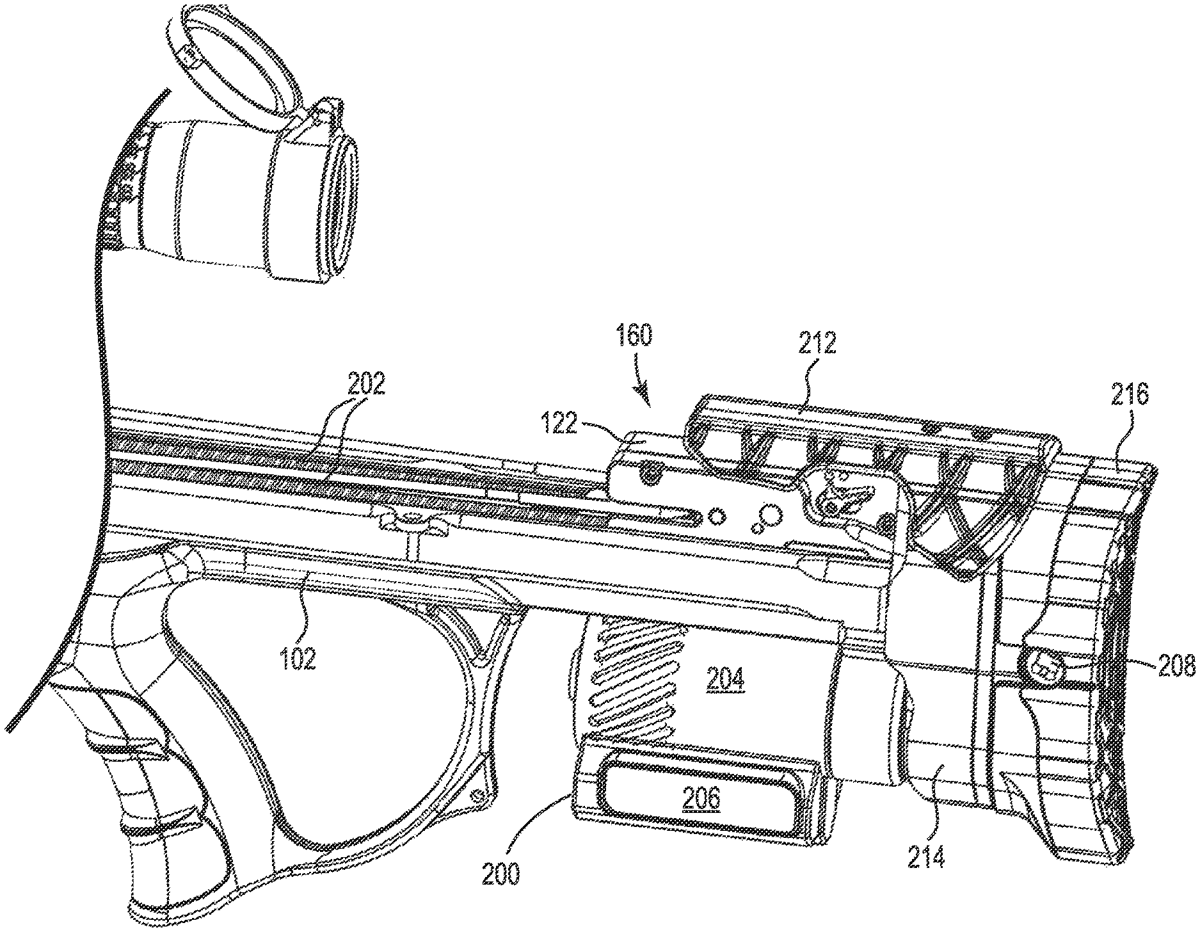

The patent describes a cocking system for a crossbow that utilizes a string carrier, screw shaft, and one-way bearing to facilitate the cocking and de-cocking of the draw string. This innovative mechanism allows for controlled movement along the center rail, enhancing safety and ease of use during operation.

Claim 1

1 . A cocking system for a crossbow that has at least a first flexible limb attached to a riser and second flexible limb attached to the riser, and a draw string that translates along a center rail of the crossbow between a released configuration and a drawn configuration, the cocking system comprising: a string carrier received by the center rail, the string carrier being configured to translate along a center axis of the crossbow between a first position to engage with the draw string when the draw string is in the released configuration, and a second position to move the draw string to the drawn configuration; at least one screw shaft attached to the center rail and engaged with the string carrier, wherein rotation of the at least one screw shaft about a first axis translates the string carrier along the center axis between the first position and the second position, wherein the first axis is parallel with the center axis; a cocking handle support axle perpendicular to the first axis; a one-way bearing rotatable about the first axis and engaged coaxially with the at least one screw shaft, the one-way bearing being configured to: permit rotation of the at least one screw shaft in a retracting direction in response to a rotation of the cocking handle support axle in a first direction to move the string carrier to the second position, and inhibit rotation of the at least one screw shaft in an extending direction such that the string carrier is retained in a current location along the center rail during a release of the cocking handle support axle; and a mechanical clutch including: a gear coaxial with the first axis and configured to rotate about the first axis and translate along the first axis; a spring coaxial with the first axis and positioned at least partially between the gear and a thrust surface; a brake washer engaged with the gear and engaged coaxially with the at least one screw shaft; a brake disc coupled to the one-way bearing and coaxial with the first axis; and a friction washer coaxial with the first axis and positioned axially between the brake washer and the brake disc, wherein the spring is configured to bias the gear in a first axial direction along the first axis, wherein the gear is configured to translate along the first axis in a second axial direction along the first axis opposite the first axial direction to compress the spring between the thrust surface and the gear to selectively disengage the one-way bearing from the at least one screw shaft to permit rotation of the at least one screw shaft in the extending direction, wherein the string carrier is configured to move to the first position when the cocking handle support axle is rotated in a second direction opposite the first direction, wherein the one-way bearing is configured to permit rotation of the brake disc in the retracting direction, and inhibit rotation of the brake disc in the extending direction, wherein the friction washer is configured to provide friction between the brake washer and the brake disc, and wherein translating the gear in the second direction reduces the friction between the brake washer and the brake disc to permit the at least one screw shaft to rotate in the extending direction. a string carrier received by the center rail, the string carrier being configured to translate along a center axis of the crossbow between a first position to engage with the draw string when the draw string is in the released configuration, and a second position to move the draw string to the drawn configuration; at least one screw shaft attached to the center rail and engaged with the string carrier, wherein rotation of the at least one screw shaft about a first axis translates the string carrier along the center axis between the first position and the second position, wherein the first axis is parallel with the center axis; a cocking handle support axle perpendicular to the first axis; a one-way bearing rotatable about the first axis and engaged coaxially with the at least one screw shaft, the one-way bearing being configured to: permit rotation of the at least one screw shaft in a retracting direction in response to a rotation of the cocking handle support axle in a first direction to move the string carrier to the second position, and inhibit rotation of the at least one screw shaft in an extending direction such that the string carrier is retained in a current location along the center rail during a release of the cocking handle support axle; and permit rotation of the at least one screw shaft in a retracting direction in response to a rotation of the cocking handle support axle in a first direction to move the string carrier to the second position, and inhibit rotation of the at least one screw shaft in an extending direction such that the string carrier is retained in a current location along the center rail during a release of the cocking handle support axle; and a mechanical clutch including: a gear coaxial with the first axis and configured to rotate about the first axis and translate along the first axis; a spring coaxial with the first axis and positioned at least partially between the gear and a thrust surface; a brake washer engaged with the gear and engaged coaxially with the at least one screw shaft; a brake disc coupled to the one-way bearing and coaxial with the first axis; and a friction washer coaxial with the first axis and positioned axially between the brake washer and the brake disc, wherein the spring is configured to bias the gear in a first axial direction along the first axis, wherein the gear is configured to translate along the first axis in a second axial direction along the first axis opposite the first axial direction to compress the spring between the thrust surface and the gear to selectively disengage the one-way bearing from the at least one screw shaft to permit rotation of the at least one screw shaft in the extending direction, wherein the string carrier is configured to move to the first position when the cocking handle support axle is rotated in a second direction opposite the first direction, wherein the one-way bearing is configured to permit rotation of the brake disc in the retracting direction, and inhibit rotation of the brake disc in the extending direction, wherein the friction washer is configured to provide friction between the brake washer and the brake disc, and wherein translating the gear in the second direction reduces the friction between the brake washer and the brake disc to permit the at least one screw shaft to rotate in the extending direction. a gear coaxial with the first axis and configured to rotate about the first axis and translate along the first axis; a spring coaxial with the first axis and positioned at least partially between the gear and a thrust surface; a brake washer engaged with the gear and engaged coaxially with the at least one screw shaft; a brake disc coupled to the one-way bearing and coaxial with the first axis; and a friction washer coaxial with the first axis and positioned axially between the brake washer and the brake disc, wherein the spring is configured to bias the gear in a first axial direction along the first axis, wherein the gear is configured to translate along the first axis in a second axial direction along the first axis opposite the first axial direction to compress the spring between the thrust surface and the gear to selectively disengage the one-way bearing from the at least one screw shaft to permit rotation of the at least one screw shaft in the extending direction, wherein the string carrier is configured to move to the first position when the cocking handle support axle is rotated in a second direction opposite the first direction, wherein the one-way bearing is configured to permit rotation of the brake disc in the retracting direction, and inhibit rotation of the brake disc in the extending direction, wherein the friction washer is configured to provide friction between the brake washer and the brake disc, and wherein translating the gear in the second direction reduces the friction between the brake washer and the brake disc to permit the at least one screw shaft to rotate in the extending direction.

Google Patents

https://patents.google.com/patent/US12480735

USPTO PDF

https://image-ppubs.uspto.gov/dirsearch-public/print/downloadPdf/12480735