US12460910 - Reduced energy marking cartridges providing a multi-phase firing cycle

The patent describes a reduced energy marking cartridge featuring a multi-phase firing cycle that utilizes a sabot and a unique valving mechanism to control combustion gas flow. This design allows for a combustion phase, a firing phase to propel a projectile, and a venting phase to expel gases, enhancing the cartridge’s functionality while minimizing energy output.

Claim 1

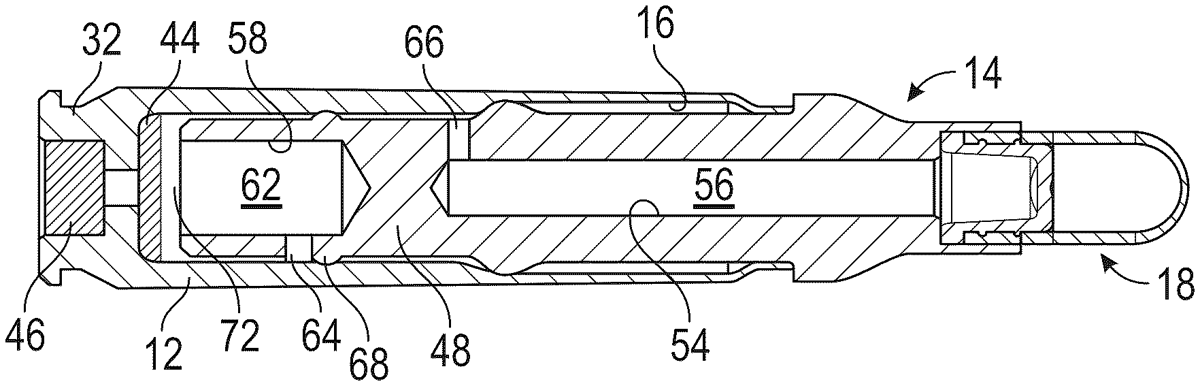

1 . A reduced-energy cartridge having a multi-phase firing cycle, the cartridge comprising: a casing having an axial bore including an aft portion extending from a base at a breech end of the cartridge and a fore portion terminating at a muzzle end of the cartridge; a sabot including a sabot body, a sabot mouth formed at the muzzle end, a blind bore extending axially from the sabot mouth into the sabot body to form an acceleration chamber, and a vent hole extending radially through the sabot body into the acceleration chamber, wherein the sabot is telescopically received in the axial bore and coupled to the casing for relative movement from a retracted position to an extended position; a first seal disposed on the sabot body and engaging the aft portion of the casing to form a combustion chamber between the base and the sabot body; a second seal disposed on the sabot body between the first seal and the sabot mouth and engaging the fore portion of the casing to form a venting chamber in the fore portion of the casing around the sabot body; a propellant disposed in the aft portion of the casing and ignitable to produce a combustion gas; and a projectile releasably disposed in the sabot mouth and configured to be propelled from the sabot; wherein the multi-phase firing cycle includes: a combustion phase, wherein the first seal engages the aft portion to seal the combustion chamber such that combustion gas pressurizes the combustion chamber for sliding the casing relative to the sabot; a firing phase, wherein the first seal disengages the aft portion and fluid communication is established from the combustion chamber for pressurizing the acceleration chamber to propel the projectile from the sabot mouth; and a venting phase, wherein the venting chamber is in fluid communication with the acceleration chamber for expelling combustion gas from the casing through the sabot mouth. a casing having an axial bore including an aft portion extending from a base at a breech end of the cartridge and a fore portion terminating at a muzzle end of the cartridge; a sabot including a sabot body, a sabot mouth formed at the muzzle end, a blind bore extending axially from the sabot mouth into the sabot body to form an acceleration chamber, and a vent hole extending radially through the sabot body into the acceleration chamber, wherein the sabot is telescopically received in the axial bore and coupled to the casing for relative movement from a retracted position to an extended position; a first seal disposed on the sabot body and engaging the aft portion of the casing to form a combustion chamber between the base and the sabot body; a second seal disposed on the sabot body between the first seal and the sabot mouth and engaging the fore portion of the casing to form a venting chamber in the fore portion of the casing around the sabot body; a propellant disposed in the aft portion of the casing and ignitable to produce a combustion gas; and a projectile releasably disposed in the sabot mouth and configured to be propelled from the sabot; wherein the multi-phase firing cycle includes: a combustion phase, wherein the first seal engages the aft portion to seal the combustion chamber such that combustion gas pressurizes the combustion chamber for sliding the casing relative to the sabot; a firing phase, wherein the first seal disengages the aft portion and fluid communication is established from the combustion chamber for pressurizing the acceleration chamber to propel the projectile from the sabot mouth; and a venting phase, wherein the venting chamber is in fluid communication with the acceleration chamber for expelling combustion gas from the casing through the sabot mouth. a combustion phase, wherein the first seal engages the aft portion to seal the combustion chamber such that combustion gas pressurizes the combustion chamber for sliding the casing relative to the sabot; a firing phase, wherein the first seal disengages the aft portion and fluid communication is established from the combustion chamber for pressurizing the acceleration chamber to propel the projectile from the sabot mouth; and a venting phase, wherein the venting chamber is in fluid communication with the acceleration chamber for expelling combustion gas from the casing through the sabot mouth.

Google Patents

https://patents.google.com/patent/US12460910

USPTO PDF

https://image-ppubs.uspto.gov/dirsearch-public/print/downloadPdf/12460910