US12460899 - Pneumatic projectile launching system

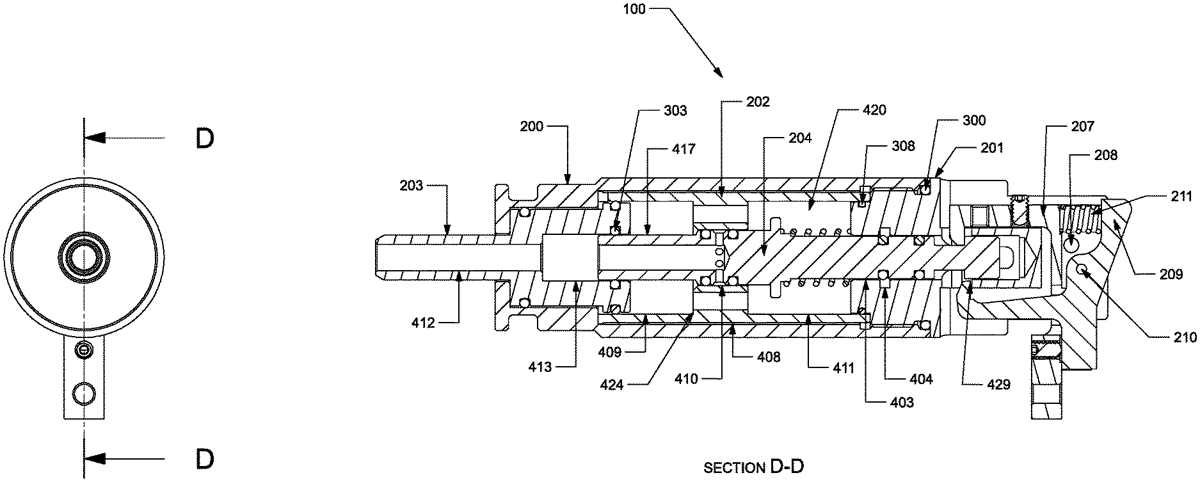

The patent describes a pneumatic projectile launching system featuring a movable nozzle that controls projectile passage and a valve mechanism that regulates airflow into and out of a volume chamber. The design includes dual sears that manage the valve’s position, ensuring precise control over the filling and exhaust states.

Claim 1

1 . A pneumatic valve mechanism comprising: a volume chamber; a valve positioned within the volume chamber, the valve moveable between an exhaust position wherein flow through from the volume chamber through the valve is facilitated while flow into the volume chamber from a fill port is prevented and a filling position wherein flow through from the volume chamber through the valve is prevented while flow into the volume chamber from the fill port is facilitated, the valve being biased to the exhaust position; a sear having a catch surface configured to engage a surface of the valve to retain the valve in the filling position and to release the valve into the exhaust position when actuated; and a secondary sear having a catch surface configured to engage the surface of the valve to retain the valve in the filling position and to release the valve into the exhaust position when actuated, wherein the catch surface of the secondary sear is located rearward of the catch surface of the sear so that the catch surface of the secondary sear does not engage the surface of the valve when the sear is engaged. a volume chamber; a valve positioned within the volume chamber, the valve moveable between an exhaust position wherein flow through from the volume chamber through the valve is facilitated while flow into the volume chamber from a fill port is prevented and a filling position wherein flow through from the volume chamber through the valve is prevented while flow into the volume chamber from the fill port is facilitated, the valve being biased to the exhaust position; a sear having a catch surface configured to engage a surface of the valve to retain the valve in the filling position and to release the valve into the exhaust position when actuated; and a secondary sear having a catch surface configured to engage the surface of the valve to retain the valve in the filling position and to release the valve into the exhaust position when actuated, wherein the catch surface of the secondary sear is located rearward of the catch surface of the sear so that the catch surface of the secondary sear does not engage the surface of the valve when the sear is engaged.

Google Patents

https://patents.google.com/patent/US12460899

USPTO PDF

https://image-ppubs.uspto.gov/dirsearch-public/print/downloadPdf/12460899